Application of Imaging Technology in Precision Measurement

Application Of Industrial Lens Imaging Technology In Precision Measurement: The Perfect Combination Of Imaging Rules And Precise Measurement

In modern industrial manufacturing, precision measurement is a key link to ensure product quality and production efficiency. As the ‘eyes’ of the machine vision system, the advanced imaging technology of industrial lenses is directly related to the accuracy of measurement. This article will focus on the application of industrial lenses in precision measurement, especially how to combine their imaging laws with precise measurement to jointly promote the progress of industrial manufacturing.

- Imaging Rules Of Industrial Lenses

The imaging rules of industrial lenses are mainly based on optical principles, especially the lens imaging principle. Simply put, when light passes through the lens, it is focused onto the camera’s sensor to form a clear image. In this process, the lens’s focal length, field of view, aperture, and other parameters play a vital role.

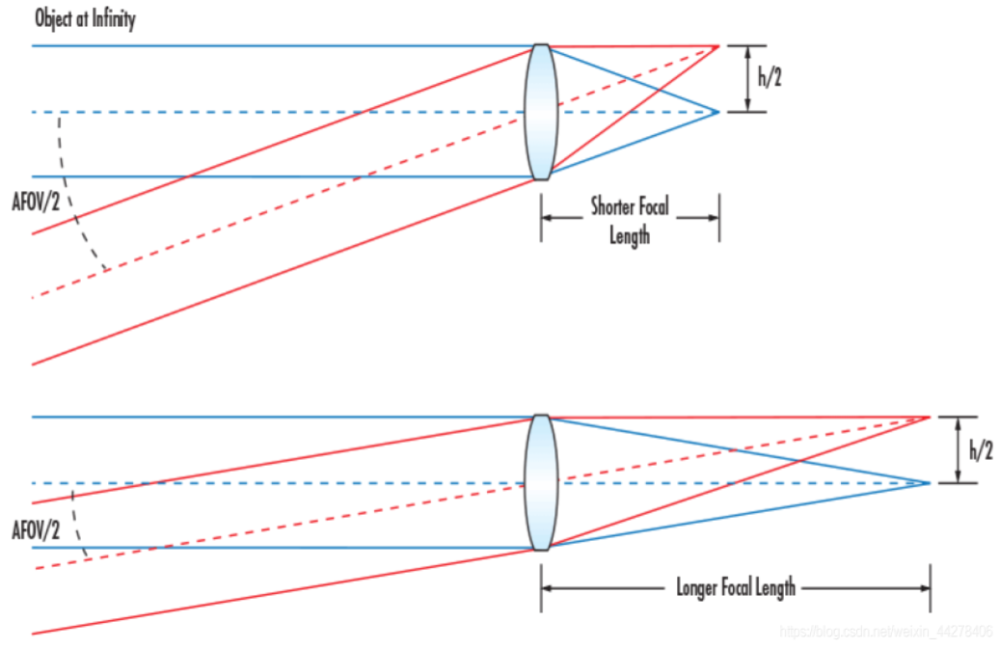

- Focal Length: Focal length determines the lens’s ability to focus light, which in turn affects the size and clarity of the image. The longer the focal length, the larger the image, but the narrower the viewing angle; the shorter the focal length, the smaller the image, but the wider the viewing angle.

- Field Of View: The field of view refers to the maximum field of view that the lens can capture. It is inversely proportional to the focal length, that is, the longer the focal length, the smaller the field of view; the shorter the focal length, the larger the field of view.

- Aperture: The aperture controls the amount of light that enters the lens, which in turn affects the brightness and depth of field of the image. The larger the aperture, the more light enters, the brighter the image, but the shallower the depth of field; the smaller the aperture, the less light enters, the darker the image, but the deeper the depth of field.

- Application Of Industrial Lenses In Precision Measurement

In the field of precision measurement, industrial lenses use their unique imaging laws to achieve accurate measurement of object size, shape, position, and other parameters. This process usually includes the following steps:

- Image Acquisition: Use industrial lenses to capture image information of the object being measured. By adjusting the lens’ focal length, the field of view, aperture, and other parameters, ensure that the image is clear, complete, and meets the measurement requirements.

- Image Processing: The collected images are transferred to a computer or image processing system for processing. Using edge detection, contour extraction, feature recognition and other algorithms, the key size and shape information of the measured object is extracted from the image.

- Data Analysis: Further analyze the processed image data to calculate the specific size, shape, position and other parameters of the object being measured. At the same time, it can also determine whether the object being measured is qualified according to the preset standards and tolerance range.

- Combination Of Imaging Rules And Precise Measurement

In the imaging process of industrial lenses, there is a close connection between the imaging law and precise measurement. On the one hand, by precisely controlling the lens parameters such as focal length, field of view and aperture, the clarity and accuracy of the imaging can be ensured; on the other hand, through advanced image processing algorithms and data analysis technology, high-precision measurement data can be extracted from the image.

Specifically, the imaging laws of industrial lenses provide a reliable image basis for precise measurement. Only by ensuring that the image is clear, complete and meets the measurement requirements can high-precision measurement data be further extracted through image processing algorithms. At the same time, the demand for precise measurement has also promoted the continuous development and innovation of industrial lens imaging technology. In order to meet the requirements of higher-precision measurements, industrial lenses need to continuously optimize their imaging performance, improve resolution, and reduce influencing factors such as distortion and dispersion.

- Conclusion

The application of industrial lens imaging technology in precision measurement demonstrates the perfect combination of optical principles and modern technology. By precisely controlling the imaging law of the lens and combining advanced image processing and data analysis technology, we can achieve accurate measurement of parameters such as object size, shape and position. The application of this technology not only improves the efficiency and quality level of industrial manufacturing, but also lays a solid foundation for the development of intelligent manufacturing and digital factories.