Application In Intelligent Manufacturing

Precise Application Of Industrial Lenses In Intelligent Manufacturing: The Eye Of Quality Control On The Production Line

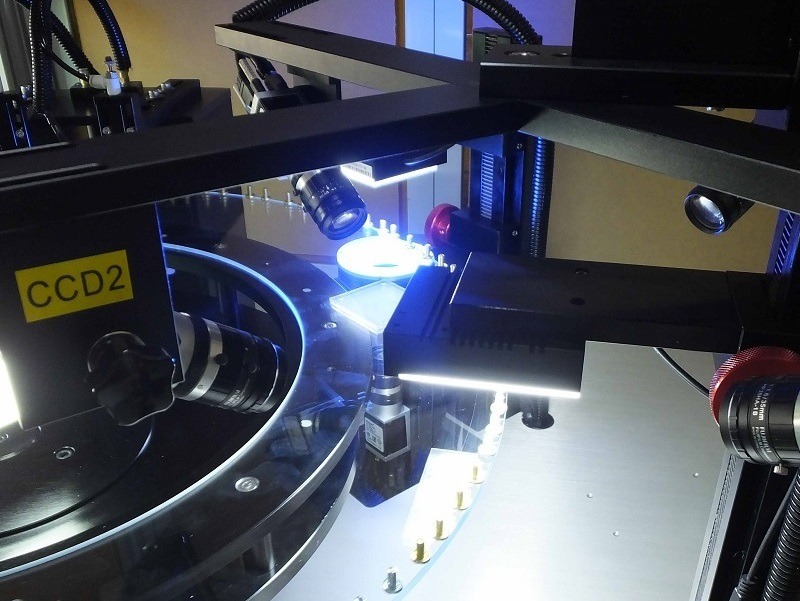

In the wave of intelligent manufacturing, industrial lenses, as the core components of machine vision systems, are playing an increasingly important role. They are not only the ‘eyes’ on the production line, but also the key link in quality control. Today, let’s discuss a practical application scenario of industrial lenses in intelligent manufacturing – quality inspection and control on the production line.

Unique advantages of industrial lenses

Compared with ordinary camera lenses, industrial lenses have higher resolution, wider field of view, stronger anti-interference ability and longer service life. These characteristics enable industrial lenses to work stably in complex and changing production environments and provide high-quality image data for machine vision systems. In intelligent manufacturing, these image data will be used in multiple links such as product inspection, dimensional measurement, and defect identification, thereby achieving comprehensive monitoring and precise control of the production process.

Quality inspection and control on the production line

1.Product appearance inspection

On the production line, industrial lenses are widely used for product appearance inspection. Through high-definition imaging technology and advanced image processing algorithms, industrial lenses can accurately identify defects such as scratches, dents, and color differences on the product surface. These defect information will be fed back to the control system in real time so that timely measures can be taken to adjust or remove unqualified products. This efficient appearance inspection method not only improves product quality, but also reduces labor and time costs.

2.Dimension measurement and positioning

In addition to appearance inspection, industrial lenses are also often used for product size measurement and positioning. Through precise image processing and measurement algorithms, industrial lenses can achieve high-precision measurement and precise positioning of product dimensions. This is especially important for manufacturing industries that require strict control of product dimensions. For example, in automobile manufacturing, industrial lenses can accurately measure the size and position deviation of parts to ensure the assembly accuracy and safety of the entire vehicle.

3.Automated assembly and sorting

In smart manufacturing, automated assembly and sorting are key links to improve production efficiency. Industrial lenses provide precise navigation and positioning services for automated equipment and robots by capturing and identifying product image information on the production line in real time. This makes the automated assembly and sorting process more efficient, accurate, and reliable. For example, in electronic product manufacturing, industrial lenses can identify and guide robots to accurately place components on circuit boards to designated locations; in logistics sorting centers, industrial lenses can quickly sort packages to the correct transportation routes based on the barcode or QR code information on the packages.

Challenges and future prospects of industrial lens applications

Although industrial lenses play an important role in smart manufacturing, their application also faces some challenges. For example, how to further improve the resolution and anti-interference ability of lenses to meet the needs of higher-precision detection? How to reduce the cost and energy consumption of lenses to improve their economy and environmental protection? In addition, with the continuous development and popularization of smart manufacturing technology, industrial lenses will also usher in a broader application prospect. In the future, we can expect to see more innovative industrial lens products and solutions emerge, injecting new vitality and impetus into the smart manufacturing industry.

Conclusion

As one of the core components of machine vision systems, industrial lenses play an irreplaceable role in intelligent manufacturing. They provide strong support for quality control on the production line through precise image capture and processing technology. With the continuous advancement of technology and the continuous expansion of application scenarios, we have reason to believe that industrial lenses will play a more important role in the field of intelligent manufacturing in the future. Let us look forward to this day together!