What is Metallographic Objective Lens?

1.Basic Optical Principles of Metallographic Objectives

The operating principle of metallographic objectives is rooted in the laws of geometric optics imaging, and their design incorporates the essence of modern optical engineering. Unlike ordinary microscope objectives, metallographic objectives are specifically optimized for reflected light observation of opaque samples. After light is emitted from a light source, it passes through an illumination system and strikes the sample surface perpendicularly. The reflected light then enters the objective lens again, forming a magnified image. During this process, the focal length (f) of the objective lens determines its basic magnification, which follows the formula M = L/f, where L is the optical tube length (usually 160 mm or infinity) and f is the focal length of the objective lens.

Numerical aperture (NA) is a key parameter in measuring the performance of metallographic objectives. It is determined by the formula NA = n·sinα, where n is the refractive index of the medium between the objective and the sample, and α is half the objective’s angular aperture. The numerical aperture of an air-immersion objective (using air as the medium, n = 1) is typically less than 1, while the numerical aperture of an oil-immersion objective (using pine oil as the medium, n ≈ 1.52) can reach approximately 1.4. The numerical aperture not only determines the resolving power of the objective (minimum resolving distance d ≈ 0.61λ/NA, where λ is the wavelength of light), but also directly affects image brightness and depth of field.

The optical correction level of a metallographic objective directly impacts image quality. Modern high-quality metallographic objectives typically utilize an infinity optical system design. The incident light, after reflecting from the specimen surface and reentering the objective, remains parallel until it converges through the tube lens to form an intermediate image. This design facilitates the inclusion of various optical accessories (such as polarization components and interference prisms) in the optical path, while also reducing aberrations and improving image flatness and resolution. Typical aberration corrections include spherical aberration, chromatic aberration, field curvature, and distortion. Advanced objectives can even achieve plan apochromat correction.

2.Structural Features and Classification of Metallographic Objectives

Metallographic objectives have a number of design features that distinguish them from biological objectives. The most notable feature is the cover glass-free correction design, as metallographic specimens typically do not require a cover glass. The surface coating of the objective front lens is also specially treated with advanced anti-reflection coating technology to significantly reduce reflection interference from the illumination light. This feature is particularly important in reflected light microscopy, effectively improving image contrast.

3.Based on the medium used and magnification, metallographic objectives can be divided into several main types:

*Correlation Objectives (5X-100X): Air is used between the objective and the sample, making them convenient to use but with a limited numerical aperture. Low- to medium-magnification objectives (5X-20X) typically have a longer working distance and a larger field of view, making them suitable for low-magnification tissue observation. High-magnification metallurgical objectives (50X-100X) require particular attention to focusing accuracy to avoid collisions with the sample.

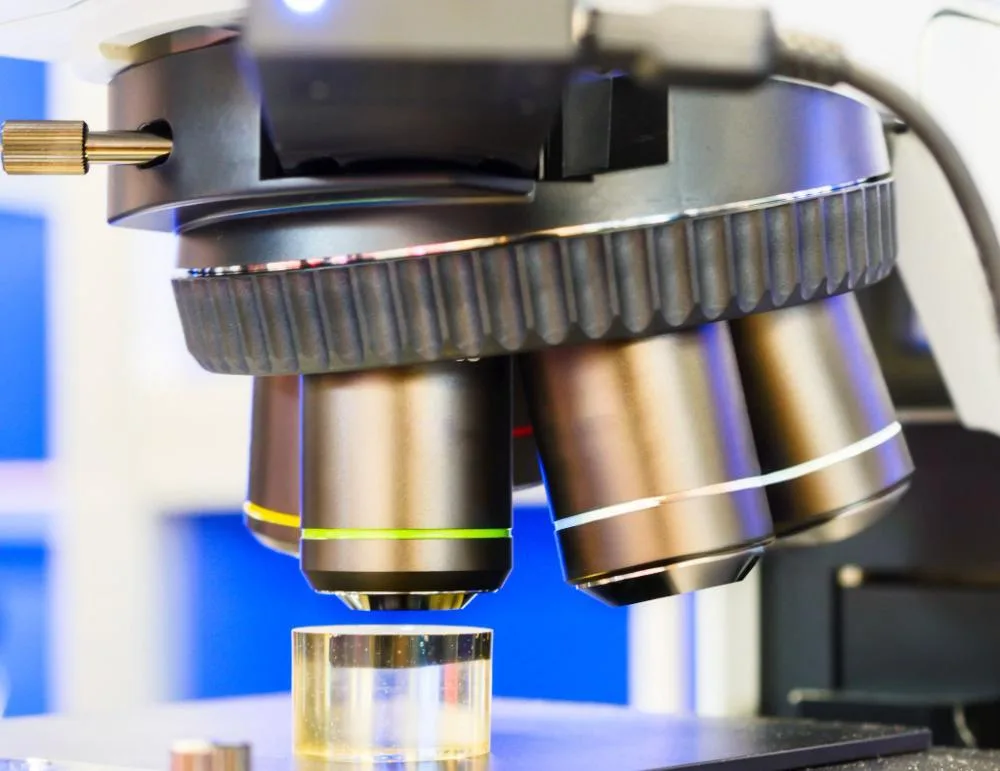

*Oil immersion objectives (50X-100X): The space between the objective lens and the sample is filled with immersion oil with a refractive index of approximately 1.52, significantly improving numerical aperture and resolution. They are particularly suitable for observing submicron structures. The lens surface should be cleaned promptly after use to prevent immersion oil residue.

*Specialty objectives include phase contrast objectives (for improving visibility of low-contrast samples), differential interference contrast (DIC) objectives (for revealing surface height differences), polarized light objectives (for anisotropy analysis), and long working distance objectives (for specialized applications such as high-temperature stages).

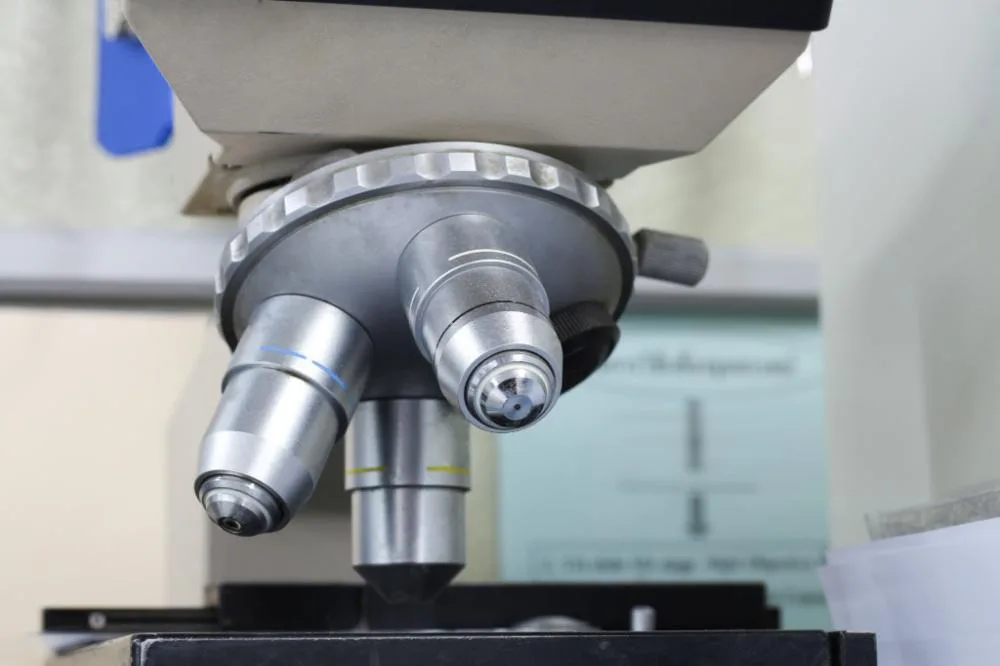

Modern high-performance metallurgical objectives generally adopt a modular design, and the objective barrel is often marked with an “M” or similar designation to distinguish them. Rotating the nosepiece allows for rapid switching between different magnifications, maintaining parfocality to ensure the sample remains largely in focus during switching. Furthermore, some advanced objectives incorporate correction collars for fine-tuning for varying sample heights or media conditions, further optimizing image quality.

4.Key Performance Parameters and Selection Considerations for Metallurgical Objectives

Selecting the appropriate metallurgical objective requires a comprehensive consideration of multiple performance parameters and application requirements. Resolution is the most fundamental consideration, determining the objective’s ability to resolve fine structures in the sample. Theoretically, under blue light illumination (λ≈450nm), an objective with an NA = 0.9 has a resolution of approximately 0.3μm. In practice, sample preparation quality, lighting conditions, and operator technique all affect achievable resolution.

-Working distance (WD) refers to the distance from the objective’s front lens to the sample. This parameter is particularly important when observing rough surfaces or using a hot stage. Generally speaking, the higher the magnification, the shorter the working distance. For example, a 10X objective might have a working distance of 7-10mm, while a 100X objective might have a working distance of only 0.1-0.3mm. Specially designed long working distance objectives offer greater flexibility in this regard.

-Image field flatness is a key indicator of objective quality. Ordinary objectives may exhibit curvature (field curvature), resulting in blurred image edges. Plan objectives, however, correct this defect through a complex lens assembly, providing uniform sharpness across the entire field of view. This is particularly important for metallographic photography and image analysis, but comes at a relatively high price.

5.The following practical factors should also be considered when selecting metallographic objectives:

·Sample characteristics: Highly reflective metal samples may require specially coated objectives to reduce glare; observing multiphase materials may require high-contrast objectives; and rough surfaces require long working distance objectives to protect against impact.

·Analytical requirements: For simple topographic observation, ordinary achromatic objectives can be used; quantitative measurements or high-precision research require plan apochromatic objectives; and polarization analysis requires specialized objectives with extremely low strain.

·System compatibility: Ensure that the objective thread standard (such as RMS) matches the microscope turret; infinity-corrected objectives must be used with the corresponding tube lens; and consider compatibility with existing lighting systems and cameras.

·Benefits: Select the appropriate objective level based on actual needs to avoid blindly pursuing the highest specifications and wasting resources.

6.Applications of Metallographic Objectives in Materials Science

Metallographic objectives play an irreplaceable role in materials science research, providing powerful tools for material development, process optimization, and failure analysis. In the field of metallurgical materials, metallographic objectives are used to observe the grain size, morphology, and distribution of materials such as steel and aluminum alloys. For example, a 100x oil immersion objective can clearly resolve the interlamellar spacing of cementite in pearlite, enabling evaluation of the mechanical properties of steel. The high resolution of the objective can also reveal crystal defects such as dislocation pits, providing direct evidence for understanding material strengthening mechanisms.

※Heat treatment process research is a traditional application of metallographic objectives. Different objective magnifications allow observation of microstructural transformations caused by heat treatment: low magnification (5X-20X) reveals macroscopic structural homogeneity; medium- to high-magnification (50X-100X) reveals the fine structure of phase transformation products such as martensite and bainite; and ultra-high magnification (when used with an electron microscope) allows analysis of the distribution of precipitated phases. Specially designed high-temperature metallographic objectives, combined with a heating stage, can also observe phase transformations in real time, providing a dynamic basis for optimizing heat treatment processes.

※The contrast performance of metallographic objectives is particularly important in the study of composite materials and multiphase alloys. By adjusting lighting conditions and selecting specialized objectives (such as DIC objectives), the contrast between different phases can be enhanced, allowing accurate determination of the proportions and distribution of each phase. Quantitative metallographic analysis software, combined with high-precision objectives, can automatically measure parameters such as grain size and second-phase volume fraction, elevating qualitative observations to quantitative analysis.

※Failure analysis is another important application of metallographic objectives. By observing fracture morphology, crack propagation paths, and surrounding microstructural changes, the cause of failure can be traced. Long working distance objectives are particularly useful in this area, enabling safe observation of uneven fracture surfaces. High-resolution objectives can also identify microscopic features such as fatigue striations and cleavage steps, enabling differentiation between different failure modes.

※In cutting-edge research, the integration of metallographic objectives with other analytical techniques is becoming increasingly common. For example, laser confocal metallographic microscopy uses an objective to focus a laser beam to obtain three-dimensional surface topography. Fluorescence metallography utilizes specialized objectives to observe the structure of materials doped with fluorescent markers. In-situ testing combines a mechanical stage with long working distance objectives to record the microstructural evolution of materials during deformation in real time.

7.Applications of Metallographic Objectives in Industrial Inspection and Other Fields

❤The application of metallographic objectives has long transcended the traditional field of metallurgy and plays a critical role in a variety of industrial sectors. In the electronics industry, metallographic objectives are used to inspect copper foil quality, solder joint integrity, and substrate defects on printed circuit boards (PCBs). High-magnification objectives can identify burrs or insufficient etching on circuit edges, ensuring reliable circuit performance. Inverted metallographic microscopes equipped with long working distance objectives are particularly suitable for observing the soldering quality of surface-mount devices (SMDs).

❤The semiconductor industry places higher demands on metallographic objectives. Observing silicon wafer lattice defects, epitaxial layer thickness, and lithographic pattern accuracy requires high-NA plan-apochromatic objectives, combined with interference contrast technology to enhance image contrast. Specially designed infrared objectives can even see through silicon to observe internal structures, while UV objectives support shorter wavelengths for improved resolution.

❤In coating technology, metallographic objectives are used to evaluate the coating/substrate interface bonding, coating porosity, and thickness uniformity. Differential interference contrast (DIC) objectives can clearly reveal surface contours just a few nanometers high, monitoring polishing quality and wear. In the automotive industry, metallographic objectives regularly inspect the degradation of thermal barrier coatings on engine components to prevent failure.

❤Geology and mineralogy also benefit from metallographic objective technology. Reflected light objectives combined with polarization devices can identify the optical properties of different minerals in ores, analyzing intergrowth relationships and genetic history. Automated mineral analysis systems, based on images captured by high-precision objectives, rapidly calculate mineral composition and liberation characteristics, guiding the optimization of mineral processing processes.

❤In forensic science, metallographic objectives assist in analyzing metal fragments, fibers, or paint flakes collected from crime scenes, tracing their origins through microstructural features. Similar principles are also applied in art authentication, observing pigment layers and base materials to determine authenticity and age.

❤In biomedical engineering, compatibility studies of metal implants require metallographic objectives to observe the tissue-material interface. The microstructure of dental alloys directly impacts their mechanical properties and corrosion resistance, necessitating metallographic examination to ensure quality. Even archaeological metallurgy relies on metallographic objectives to reveal the manufacturing techniques and historical evolution of ancient metal artifacts.

8.Technical Advances and Future Trends in Metallographic Objectives

Metallographic objective technology continues to evolve to meet the growing analytical demands of materials science. Optical design innovation is the most significant development. Newer objectives utilize more lens elements and specialized optical materials, such as fluorite and extra-low dispersion glass, to further eliminate residual aberrations. The use of aspheric lens technology simplifies objective structure while improving performance, further enhancing plan-apochromat correction.

The concept of intelligent objectives is emerging. Objectives with integrated microprocessors and sensors can automatically identify their parameters (such as magnification and NA) and communicate with the microscope system for optimized settings. Some high-end objectives are equipped with motorized focus and correction collars, which can be remotely controlled via software, making them particularly suitable for automated inspection systems and in-situ experimental environments.

Multifunctional integration is another development trend. Modern research-grade metallographic objectives are often designed to accommodate multiple observation modes: brightfield, darkfield, polarized light, DIC, and fluorescence. By using switchable optical components or intelligent coating technologies within the objective, the same objective can be adapted to different imaging requirements, improving experimental efficiency and reducing costs.

Extreme applications are driving the development of specialized objectives. Objectives designed for high-temperature experiments (up to 1700°C) utilize heat-resistant materials and cooling structures; objectives designed for corrosive environments feature reinforced sealing and anti-corrosion coatings; and high-angle observation objectives support EBSD analysis, meeting the needs of crystal orientation research.

Breaking the limits of resolution is a constant pursuit in objective technology. Super-resolution metallographic microscopy utilizes structured illumination or near-field optics to break the Abbe diffraction limit, extending optical resolution down to the nanometer scale. This technique requires specially designed objectives and precise coordination with the illumination system, opening up new dimensions of observation in materials science.

In the future, metallographic objectives will be more deeply integrated into digital workflows. Objectives’ built-in calibration data can be directly used in image analysis software to achieve precise dimensional measurements. Integration with artificial intelligence systems enables objectives to automatically identify optimal observation parameters and even preliminarily determine tissue characteristics. With the advancement of large-scale projects such as the Materials Genome Project, the demand for high-throughput metallographic analysis will drive the development of objectives towards higher speeds and higher throughput, while maintaining superior optical performance.

9.Conclusion: The Value and Future of Metallographic Objectives

From traditional metallurgy to nanomaterials research, metallographic objectives serve as a bridge between the macroscopic world and the microscopic structure, their scientific value and industrial importance are self-evident. An excellent metallographic objective requires not only sophisticated optical design and manufacturing processes, but also a deep understanding of the observational requirements of materials science. Modern metallographers should understand the performance characteristics of objective lenses and rationally select and use them based on specific application scenarios to fully realize their observational potential.

With the increasing complexity of material systems and the continuous improvement of analytical requirements, metallographic objective technology will continue to advance. On the one hand, it will develop towards higher resolution and stronger correction capabilities, while on the other hand, it will focus on multifunctional integration and intelligent operation. The integration of new optical materials, precision machining technologies, and computer-aided design will give rise to even more powerful objective products. Furthermore, the combination of metallographic objectives with other characterization techniques (such as Raman spectroscopy and atomic force microscopy) will also expand the boundaries of their application.

Against the backdrop of manufacturing transformation and upgrading and accelerated materials innovation, metallographic objectives, as fundamental and critical analytical tools, will continue to provide indispensable technical support for quality control, process optimization, and scientific research. A deep understanding of the principles and applications of metallographic objectives is of long-term significance for materials scientists to effectively conduct microstructural analysis.